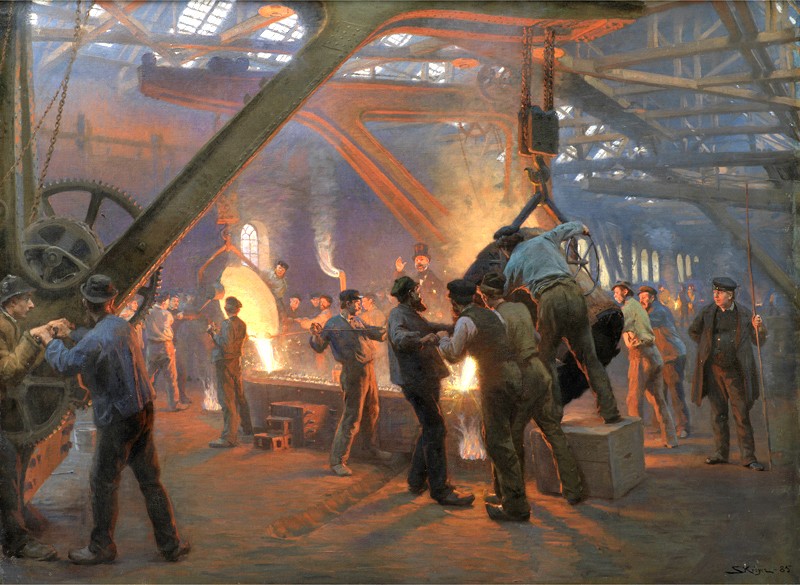

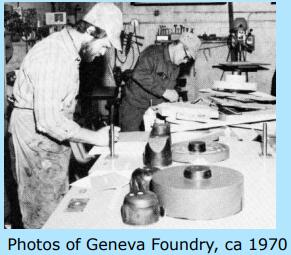

How a Foundry Works during 1970s

Design and make a pattern. Engineers, draftsmen, and pattern makers collaborate to make a wood model.

Create a mold. The pattern is pressed into sand in a box, which makes the outline of the casting. Two halves are joined to make one hollow piece. If the final product is hollow, cores are made to create the cavities.

Fire the cupola. The cupola is a tall stack furnace with a sand floor and a tap hole at the bottom, forced air inlets on the middle, and an opening at top. Layers of coke (distilled coal) and pig iron (refined iron ore) are burned in the cupola; more fuel and iron are added at the top (called “charging”) as molten metal is drawn off the bottom.

Pour the molds. Hand-carried ladles are used to pour small molds, while overhead cranes are used for large molds.

Finish the pieces. After the castings cool, they are shaken out (removed), and they go through a series of cleaning and grinding steps to be finished.

Clean the cupola. Slag (impurities) and sand are emptied from the bottom of the cupola at the end of firing. After cooling, they are hauled away and the cupola is set up for the next firing.

Modern improvements in the late 20th century - “stack scrubbers” to reduce pollution, electric furnaces to eliminate the use of coke, and computer automation – have altered foundries, but they remain hot and hazardous.