Difference Between Sand Casting and Die Casting

Difference Between Sand Casting and Die Casting

Sand casting and die casting have some similarities, yet they are different when it comes to their production. Both processes are methods for producing castings out of various types of metals. Sand castings can be produced from a variety of metals, but the most popular metals are grey iron, ductile iron, steel, and aluminum. Die casting mostly feature non-ferrous metals such as zinc, copper, aluminum, magnesium, lead, tin, etc.

Both methods of casting use a pattern or mold to create the cavity, then molten metal is used to fill the cavity creating the desired part. That is where the similarities between the two methods end.

![]()

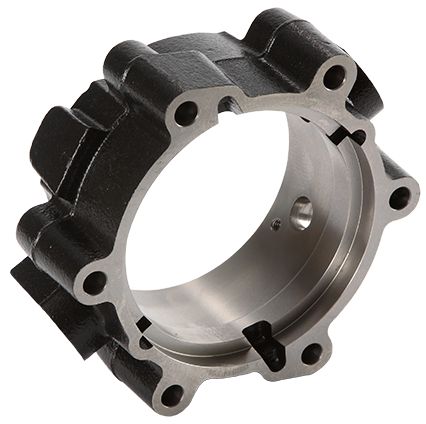

In the sand casting process a pattern, or mold, is needed to create the empty cavity within the sand to create the shape of the desired part. This means that the pattern could be made out of a variety of materials, such as wood, metal, polyurethane board, or even plastic. The material of the pattern depends on how many castings it is needed to produce. The pattern then becomes part of a core box which is necessary for final production. A core box (pictured above) is just that, a box that the pattern is placed in, filled with sand, then packed to form the shape of the pattern. The sand, which is chemically bonded to hold its shape, is then removed and can be filled with molten metal.

Die casting also requires a pattern, or mold, to produce the metal casting, except these patterns require much more. The process of die casting involves forcing molten metal metal into a mold under high pressures. Unlike sand casting, the molten metal will be in direct contact with the mold during the die casting process. This means that the pattern/mold must be able to withstand immense pressures and extreme heat repeatedly. Typically, the mold is created out of hardened steel as it can withstand the heat and pressure associated with die casting.

The equipment needed for die casting combined with the costs to produce patterns/molds out of hardened steel make up the large capital costs associated with die casting. Due to the high costs, die casting tends to be reserved for high volume production runs as it would just not be cost effective for smaller quantities. Also, die casting is a good method of limiting and/or eliminating porosity issues since the metal is forced into the die under high pressure.

Sand casting is much more cost effective at smaller quantities due to the resources and equipment needed to produce them. The pattern can be created out of a variety of materials and the sand used in the casting process can be reused further helping reduce costs. Each method of casting is capable of producing high quality castings, but each method has its own positives and negatives. Here with Dandong Hengrui Foundry, we specialize on both processing ways, under automation production line.